- /Sections

- Textiles

- Process

- Inks

- Workshop

- Other Factors

Organic T Shirt Printing: should be just that. We supply organic T-shirts manufactured by forward thinking ethical suppliers. When such great effort is made to deliver a sustainable organic product to us, it makes no sense to then add PVC screen prints to these environmentally friendly T-shirts. Blackwater Studios screen prints are made with water based inks only, and no plastic film positives are used to create the screens.

Pthalate free inks are certainly an improvement on older plastisol inks, but still contain PVC. Is your “environmentally friendly” screen printer using plastic inks? The answer might surprise you. Tons of plastic enters the environment every year on the front of T-shirts, and this is not recyclable.

Organic Textiles

Organic Cotton

Ethical: Eco friendly. Free from pesticides, and does not use synthetic fertilisers. The benefits are far reaching for those involved in the growing and manufacturing, as well as the end user. It is also free from GM (genetic modification). Here are some of the key benefits.

Salvage

Recycled mixes: The content of these T-shirts can vary a little from one manufacturer to another. The cotton content is organic, and pre-consumer, and will consist of cuttings from the pattern making process. It also contains a percentage of post consumer polyester, from recycled bottles.

Natural Alternatives

Cotton Alternatives: Used as a percentage mix with organic cotton, and are mostly bamboo, hemp, and viscose materials. These all have their own pros and cons, and some have an intensive production process, but the finished T-shirt will be extremely durable. All these alternatives help take the pressure off cotton as a crop.

Please Note: Although our preference and recommendation (especially if you’re a brand and looking for a high quality product) is for organic garments, we do also have non-organic garments featured on our website for customers whose budget may not be able accommodate these products.

If you’d like to only see our organic products, see the link below.

Choosing Inks and Print Styles

Waterbased Ink

A water based ink is made up of pigment, resin, and water. Other additives such as anti foam, and surfactants are also used. They are not entirely harmless/neutral in their make up. But they avoid the use of PVC, and solvents.

Water based inks are biodegradable, and if dealt with in the correct way, will release less harmful toxins into the environment than the plastisol alternative. When printing on to lighter coloured materials with darker pigments the resulting prints do not require excessive amounts of energy to fully cure.

Discharge Printing

The drawback with a water based ink is its lack of opacity, and one solution to this problem is discharge printing. Bleaching the colour out of the garment, before applying your water based dyes. This process requires higher temperatures in the conveyor dryer, but it does not require any flash curing on the press. The energy used to flash dry between applied colours when printing plastisol inks is significant, and in our opinion plastic inks should not be promoted as needing less energy to cure.

Note: Discharge works best on 100% cotton garments. For other fabric compositions, it’s a good idea to get in touch with complete details of your requirements so that we can offer guidance.

Solvent-free Waterbased Printing

Waterbased printing with discharge process.

Ghost Fishing

Sustainable screen printing on to organic T-shirts for Surfers Against Sewage.

Want to know more about plastics in the environment?

Clean Environment for ECO FRIENDLY T shirt Printing

Work Surfaces

It is important to keep work surfaces clean in a workshop which handles both organic, and non organic T Shirts. The few Soil Association Accredited workshops will still routinely handle non organic brands. They follow strict procedures to prevent cross contamination.

Machinery

Squeegees and flood bars can easily become contaminated by plastic inks, and leach toxins into a water based print run. Our screen printing machines are used exclusively for water based screen printing. T-shirt pallets can be re-covered to prevent transfer of non organic lint.

Air quality

It only takes a couple of hours to fill a screen printing studio with lint, and spray glue. Carbon air filters help to keep this air pollution to a minimum. Rollers now apply glue, rather than the more commonly used aerosol spray glues and this helps in keeping our workshop clean.

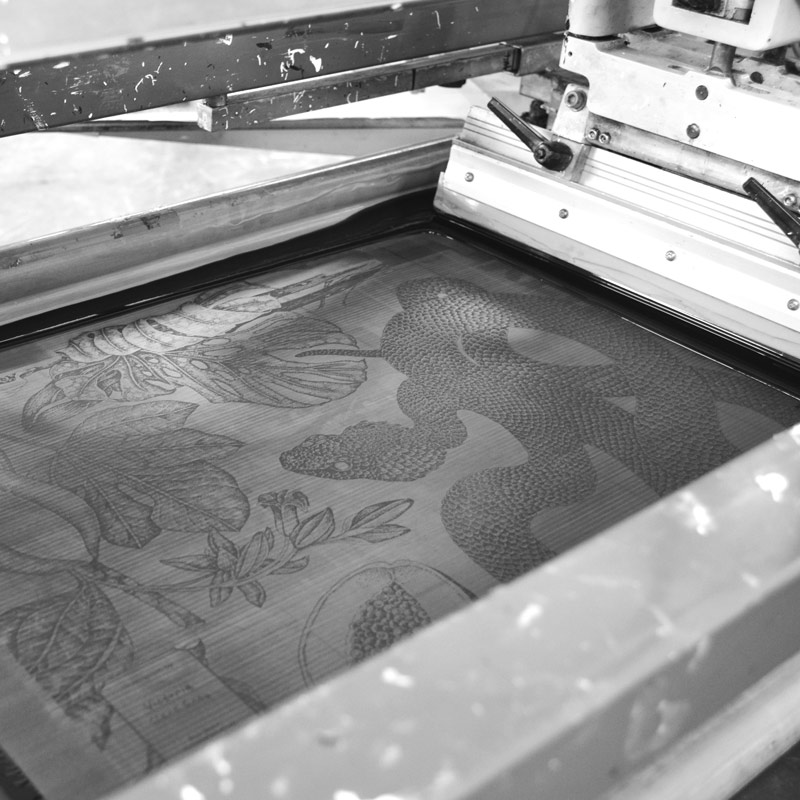

Efficient No-Waste Screens

Plastic film is no longer used in the production of our screens for t shirt printing. The process of printing ink onto plastic film, and taping it to a screen to be exposed, has been replaced with a direct-to-screen system. This allows us to bypass any film usage at all, and saves consuming hundreds of meters of plastic film and sello tape every month. Direct to screen also reduces the time required, and margin of error in the production of screens.

Blackwater Studios screen exposure system is now an LED based one, and this change from Halogen light sources further reduces our power usage.